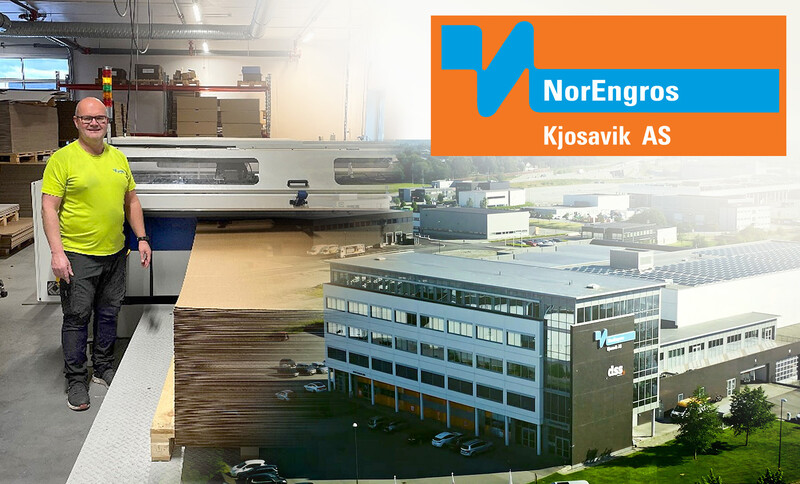

Norengros is a national supplier of packaging for industry, catering, large households and trade companies in Norway. Their company Norengros Kjosavik, based in Stavanger, wanted to be able to offer short to medium run corrugated boxes in bespoke sizes. Fast turnaround, and the ability to personalise and print boxes was specified, from a machine manufacturer who could provide reliable service and parts back-up. Edvard Schneidler AB, one of Norway’s leading machinery suppliers, recommended a Kolbus Autobox machine.

The company bought an Autobox AB 300, the perfect boxmaking machine for short to medium run boxmaking. To enable non-stop feeding, by a single operator, an Autobox AF 300 AUTO-FEED, with scissor lift was specified. The AF 300 feeds an unlimited length and the self-rising scissor lift, mounted in a small pit, to maximise pile height.

Norengros Kjosavik also invested in an Autobox FP 300 FLEXO-PRINT unit. This has a printing area of around 1000mm x 1000mm, with a minimum repeat of 350mm. The servo drive technology delivers extremely quick and accurate set up. A new job can be set up in as little as five minutes as 95% of set-up is done automatically for the operator.

Managing Director of Norengros Kjosavik, Gunnar Kjosavik, said: “There were two important criteria for us when considering this investment: we wanted a reliable machine with good runnability; we demanded a solid service set-up. After careful consideration, the Kolbus Autobox machine was our first choice.”

Autobox local agent Björn Åsell from Edvard Schneidler AB said: “We are delighted to have Norengros Kjosavik as our customer! They performed an extensive research process before deciding which equipment and configuration to invest in. Now after seeing what they can achieve, I’m certain it was the right choice.”

"The new machine complements our existing short run machines including three Kolbus AutoBox machines that we have run successfully for the past 15 years"

Add-on modules:

Box Printing:

Box Gluing: