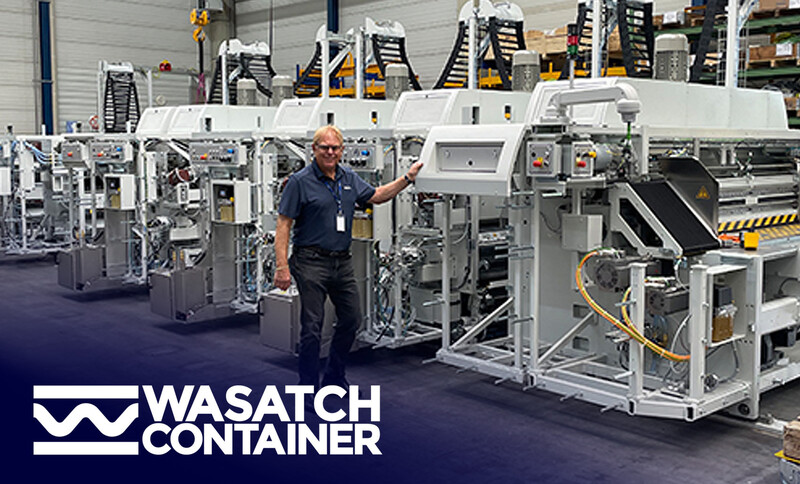

Salt Lake City based Wasatch Container recently installed a five-color 115” Kolbus RD 115S in an effort to expand productivity and add value to their Intermountain West customers. The Kolbus flexo rotary die-cutter is housed in the newly expanded 110,000 sq ft facility and is expected to be a “game changer” for the family-owned business.

Wasatch Container is a sheet plant, founded by Jerry Frisch in 1995, now managed by his children, Lauren and Ryan. Since the beginning, the company has operated out of a 30,000 sq ft facility and has served the Salt Lake Valley (Intermountain West including Utah and the surrounding states).

In 2020, Frisch was looking into purchasing a flexo rotary die-cutter to add to his existing converting equipment. However, there was no way that a new machine would fit into their plant as it stood. This led Wasatch Container to invest in a large-scale expansion project to increase plant space by nearly 400%. Like with all major investments, Frisch researched the latest machines on the market and consulted with industry professionals.

The German built Kolbus RD 115S fully servo flexo rotary die-cutter was launched to the North American market in 2020 and quickly caught the attention of Frisch and others in the corrugated industry. “We looked at the 4-5 major die cutters on the market and ended up choosing the Kolbus RD 115S,” said Frisch, who purchased the Kolbus machine in late 2021. “The machine has an incredible run speed, impressive print registration, and the delivery time fit our schedule perfectly. Everything about this machine is top-notch and high-quality, but what really attracted us to this machine was the top and bottom print capabilities and the automation.”

Frisch continued, “The RD 115S will be a ‘game changer’ for Wasatch Container and its customers. The advanced technology and automation on our RD allows for quick set ups, increased throughput in our plant and shorter lead times for our customers.”

Frisch explained that the goal of this investment is to increase value to their customers, not only in terms of raising the bar for print quality, but automation as well. “The ability to print on both sides of the box in a single pass is a huge productivity gain. In addition, having the ability to print to such tight specs will be a great value add to our customers.”

“Wasatch Container will be able to leverage the graphics print capabilities of tight registration and refined ink metering, as well as productivity of a feature-rich die cutter,” said industry consultant, Chris Heusch of ARCH Inc., who initially recommended that Frisch take a look at the Kolbus machine.

The five-color RD 115S at Wasatch Container comes fully loaded with options including the camera register control system, pneumatic print plate locking, motorized print plate skewing, variable print plate thickness capability, print & die-cut image shrink and stretching capability, and the latest IR drying system from JB Machinery. “We believe that this machine is set up so well that it’ll be the top printing machine in the Intermountain area,” adds Frisch. “We couldn’t have been more thrilled to see the machine delivered at our facility on time and perfectly to spec. Although our construction project is still underway, nearing completion, the Kolbus team has been accommodating and flexible throughout the entire process.”

“The team at Kolbus is a pleasure to work with and we trust their ability to support and service this machine in the US,” said Heusch.

“Overall, working with the Kolbus team has been great. The sales team is extremely knowledgeable, and the installation team was professional and thorough,” said Frisch. “We have full faith in Kolbus’ commitment to Wasatch and that they will be a fantastic partner throughout the life of the machine and beyond.”

“We are just as excited as they are about this installation and we look forward to continuing our partnership and supporting the Wasatch team any way we can to guarantee their success,” said Phil Eads, Corrugated Sales Manager, Kolbus America.

Published by The Packaging Portal and IPBI North America, Spring 2023

"Over the last 35 years I have been heavily involved with most aspects of our manufacturing and I can honestly say the AutoBox is probably, for what it does, the best machine I have ever worked with"

Add-on modules:

Box Printing:

Box Gluing: