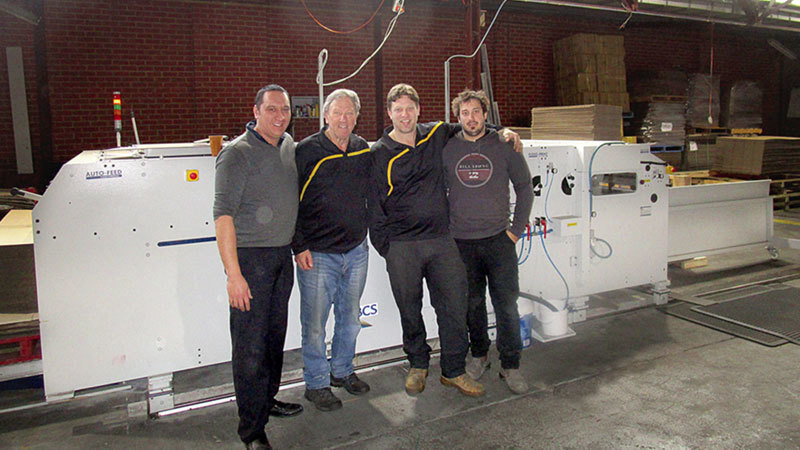

Ace Packaging Containers based in Victoria, Australia are moving into the on-demand, short-run box custom box market, after installing a Quick Set BCS Autobox box maker with inline flexo printer.

Run by Nick and Philip Langdon, the duo say they have seen a change in the market, as customers request specific size boxes in runs of 10-500, expecting delivery within a short time frame. They say that finding a box Plant who could meet the criteria was difficult. They just were not interested in supplying us with short runs.

“After some research, we found BCS, a UK company that only make short run custom box makers and associated equipment”.

“The system we installed has an auto feeder taking stock board from a pallet, which in turn feeds into the main machine to deliver slotted, creased and cut boxes. It only requires one operator. The setup process is tool-free, via a touch screen, with a setup time of sixty seconds. The machine is networked and jobs can be input from the sales office computer.”

A BCS Progluer straight-line gluer and strapping machines complete the short-run set up.

Nick Langdon says, “Our core business of selling stock boxes complements the new JIT / On Demand customised box business perfectly. We can still give our clients large quantities but also fulfil requirements for custom size boxes in small lots.”

The company says that the growth of digital print has seen the need for small quantities of custom size boxes, which it now offers.

“Anyone sending product by post or courier air freight understands that the right size box is required; filler is just not an option due to the cost".

Ace Packaging Containers is a family business that has been operating in Melbourne since the 1950s. Started by Dave Langdon in Richmond, it first sold wooden tea chests around the world, before moving into cartons and boxes for packaging.

Neil Southerington, Asia-Pacific Sales Manager for BCS says, “The Autobox is a fully automatic box maker. The machine Ace has installed has a flexographic printing unit. It can also be offered with inline digital inkjet, or both.

“The size ranges from a very small box, say 100x100mm, to boxes big enough to take large furniture, around 2.6m by 5m.

“The market is radically changing because of digitalisation. Previously our customers were traditional box makers, and producers of corrugated board. With the advent of e-commerce business, and POS display, it has driven a new generation of buyers for us, who don’t require 5,000 boxes, but might need 500 boxes in 200 different sizes, and 20 different styles in a day!"

“Our AutoBox line is already making us more money than we get from a US$2.5m Flexo!”

Add-on modules:

Box Printing:

Box Gluing: