Still based in Basildon, Essex, LVB Packaging have added two further divisions to their corrugated carton manufacturing facility: stratocell and foam packaging, and polystyrene packaging manufacture. But it has been Kolbus Autobox’s expertise in continued R&D, design, and production of their range of corrugated cardboard machines that has enabled LVB Packaging to satisfy their expanding customer base in this area.

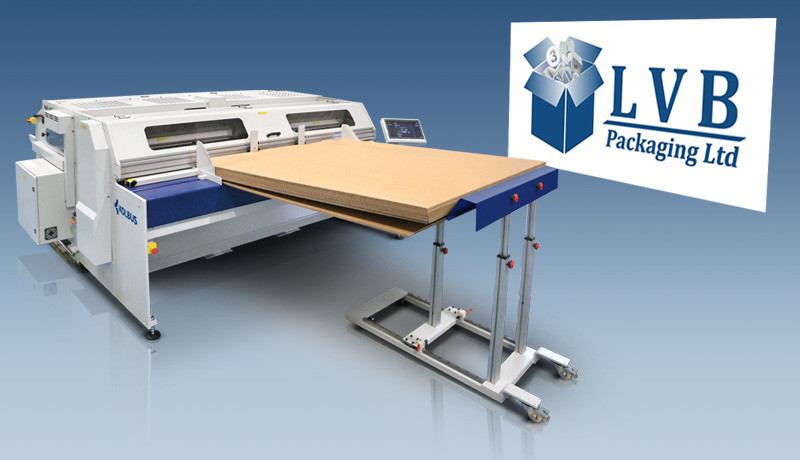

LVB supply both standard and custom corrugated boxes, they help customers by designing bespoke solutions to difficult packaging jobs when required. Increasingly these are needed in short to medium run lengths and this is where their latest Kolbus Autobox machine – an AB300 Boxmaker -comes into its own.

LVB opted for an easy-to-use standalone unit to produce the larger volume, cut to size work. With In-line slitting and printing this more advanced AB300 could do what it does best. Additionally smaller (200mm) and larger (700mm) slotting knives were specified to cater for bigger 0409/0411 work.

Small to medium boxes are now running at around 800 boxes per hour with a typical setup time of less than 60 seconds. Only a single operator is required with the semi-automatic feeding unit needing just occasional topping up. With such a fast run speed it makes producing short to medium run lengths of boxes from cut to size board extremely efficient. Adding this extra capacity has enabled LVB to reach out to a broader customer base and complete jobs even quicker than before.

LVB have grown from a start-up business 20 years ago to the significant sheet plant they are today. Their new AB300 box maker joins a similar machine plus range of Autobox Boxmakers with additional features including an FP300 to incorporate flexoprinting and a MC300 Multicut for extra box styles. These operate alongside a PG100 gluer and RS200 slitter.

LVB’s Mr Bhudia commented: “I have been working with Autobox for many years. They offer a brilliant industry leading machine that does just what it says. Also, if we need a part, we can contact the manufacturing site and get it that day. We need our machines to run every day, we need to know that we are supported.”

Arran Sethi, Kolbus UK Sales Manager said: “Lalji has been a dependable customer from day one. He remembers the days of our old pneumatic slotting machines that he used to operate 20 years ago. It is safe to say that both companies have grown since then! We talk regularly. And when he asked for a new machine quote, we were able to supply the specification he was looking for within eight weeks, to cater for his demand.”